IEC-publication 257 (1968) and Amendment no.The most important standards for fuse-holders, which specify requirements, characteristics and testing methods are: How much is available to spend on safety and reliability?.Should the fuse only be accessible from outside the appliance?.Should the end customer of the appliance have access to change the fuse?.How often will the fuse need to be replaced?.Will the fuse need to accessible for replacement?.The first step is to answer the following questions: Click here to start this process.Selection of the Fuse and Holder Solution MAVERICK Technologies is a CSIA member as of ĭo you have experience and expertise with the topics mentioned in this content? You should consider contributing to our CFE Media editorial team and getting the recognition you and your company deserve. MAVERICK delivers expertise and consulting in a wide variety of areas including industrial automation controls, distributed control systems, manufacturing execution systems, operational strategy, business process optimization and more. Joe is a senior designer at MAVERICK Technologies, a leading automation solutions provider offering industrial automation, strategic manufacturing, and enterprise integration services for the process industries. This is especially true for non-redundant I/O in safety systems.ĭo you have published standards and practices? If not, by following the suggestions above, you can be assured that your I/O modules, field devices and control panel wiring will be protected. A blown fuse can cause a false system shutdown and add additional points of failure in a system. Be aware of the ramifications for fusing I/O in safety systems.

Make sure that the fuse size selected does not exceed the amperage rating of the wire.ġ1.

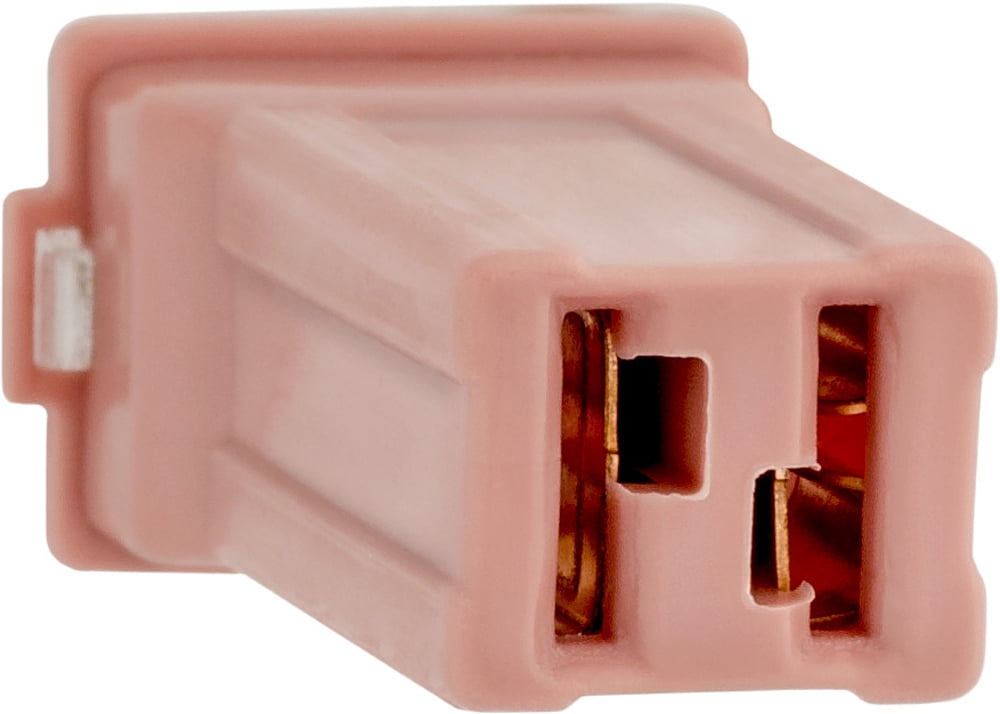

If several I/O points of any type are connected to the same field device, it may be preferable to protect all of these points with a single fuse so that there is a single disconnection point for the device.ġ0. There may also be times when you do not want to fuse a single control point, but rather want a whole group fused together for safety or other sound engineering reasons. Going by the book, you probably don’t want to limit your total current at 2 amps, so you put an 8 amp fuse on the module supply, and 2 amp fuses on each output. For example, a module may have a total current rating of 8 amps, but each output is only rated for 2 amps. Output modules have an overall module current rating and a per point current rating. Indicating type fuse holders require different types depending on voltage level and voltage type.ĩ. Fuse holders are preferred to be blown fuse indicating type if budget allows, with touch-safe swing-out arms where possible. However, some customers may require the 0.25 in x1.25 in format. The 5x20mm fuse size is popular and often used for I/O fusing since it offers a minimum footprint size that fits well with traditional cage-type terminal blocks. Generally, fuses for I/O will be fast-acting type for better protection (whereas power distribution in a panel will require use of time-delay fuses).Ĩ. Be aware that extremely low amperage fuses are expensive and usually not warranted. Since fuses are replaceable items, there should also be consideration to selecting non-overlapping fuse sizes to facilitate proper replacement. Fuse selection should give consideration to minimizing the number of replacement parts which must be stocked. Ceramic fuses are generally a better choice in most applications.ħ. Be aware that in food production or facilities that limit glass, glass fuses may not be allowed. If I/O modules are electronically fused or current limited there should not be a need to use external fuses.Ħ. Check the I/O module documentation for on board fusing details and make sure any external fuses coordinate with on board module fuses.

0 kommentar(er)

0 kommentar(er)